The Project

Role:

UX Designer & Systems Designer (initially Industrial Design)

Timeline: 8 weeks

Team:

Industrial Design team (engineers, PMs);

transitioned to solo UX/HMI design

Deliverables:

System workflow & journey maps, cartridge logic, dry-run demo findings, wireframes, HMI prototypes

Overview

This project aimed to create a first-of-its-kind automated machine to scan Petri dishes, a process traditionally done by lab technicians.

The machine would pick up, scan, image, and sort each dish using a robotic arm, classifying them into positive/negative/error cartridges.

I played a key role in designing both the machine system and the HMI from scratch.

I initiated the end-to-end user journey mapping that aligned the entire team on how the system should work. Later, I was responsible for designing the first conceptual interface that would make the system safe and intuitive to use.

I was key part of designing both the system workflow and the sole designer for the interface, ensuring the machine would not only work conceptually but also be safe and usable from day one.

The Machine

The Challenge

There was no existing machine or interface — everything had to be conceptualized from scratch.

Key challenges included:

-

Handling two dish sizes (65mm & 90mm) within cartridges.

-

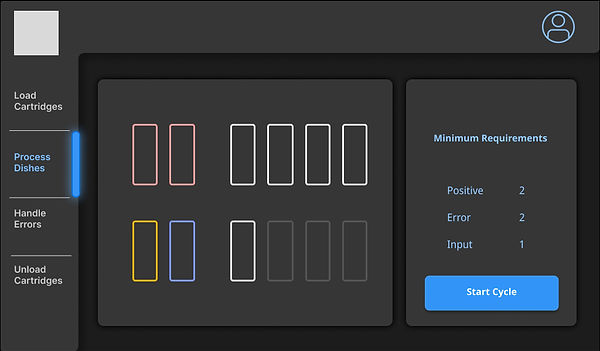

Designing a cartridge system that supports full, empty, and result-specific cartridges (positive, negative, barcode error, scan error).

-

Mapping robotic arm actions for pick–scan–image–sort.

-

Designing an HMI that prevents catastrophic errors like aborting cycles mid-process or misloading cartridges.

The biggest risk was human error: a misloaded cartridge or an accidental abort could waste hours of work and damage expensive equipment.

Research & Systems Thinking

I initiated and led user journey mapping, tracing every step in the life of a Petri dish:

-

Labeling & Collection: Dishes labeled and collected from field sites.

-

Loading into Cartridges: Technicians placed dishes into cartridges with handles for easy transfer.

-

Incubation: Cartridges stored in incubators until ready for scanning.

-

Loading Machine: Operators moved cartridges to the machine, which required:

-

≥1 full cartridge for scanning

-

2 empty contamination cartridges (for positive results)

-

1 empty barcode error cartridge

-

1 empty scan error cartridge

-

-

Machine Processing: Robotic arm picked, scanned, imaged, and sorted dishes into correct cartridges.

-

Unloading & Post-Processing: Operators removed cartridges for further lab work or reuse.

Dry-run demos (simulations)

• Ran physical walk-throughs using mock cartridges and props to simulate the full journey (label → incubation → transfer → machine → post-processing).

• Observed common operator mistakes (insufficient empty cartridges, wrong cartridge placement) and recorded points that required screen guidance.

• Outcome: confirmed the need for two contamination cartridges for positives, dedicated error cartridges, and a double-confirm for aborting cycles.

User Journey map

The system included multiple physical actions that the user would have to perform at various locations.

Thesse were divided into pre-machine, at machin and post-processing.

The user would be required to physically load the machine with minimum number of petri dish stands to start.

Knowing this was essential as the screen ux would have to prompt and guide the user for each physical action

Information Architecture

Using tools such as

-

Card sorting

-

testing paper Prototypes

-

user journey map

The HMI process was divided onto 4 stages

Visual Design

Light Mode

Dark Mode

Figma Prototype

Outcome and Impact

• System blueprint completed and adopted by engineering as the baseline for prototype build.

• Simulation-driven changes (cartridge logic & confirm dialogs) prevented 90% of the error states we simulated during dry runs.

• Stakeholder feedback: “The concepts anticipate mistakes before they happen — exactly what we needed for an MVP.” — Engineering lead

Reflections and Learnings

What went well: cross-disciplinary journey maps aligned engineering and design early, reducing rework.

Challenges: conceptual work meant we lacked live hardware for real user testing.

Next steps: run simulated usability tests with lab technicians and add accessibility checks (color-blind friendly alerts).